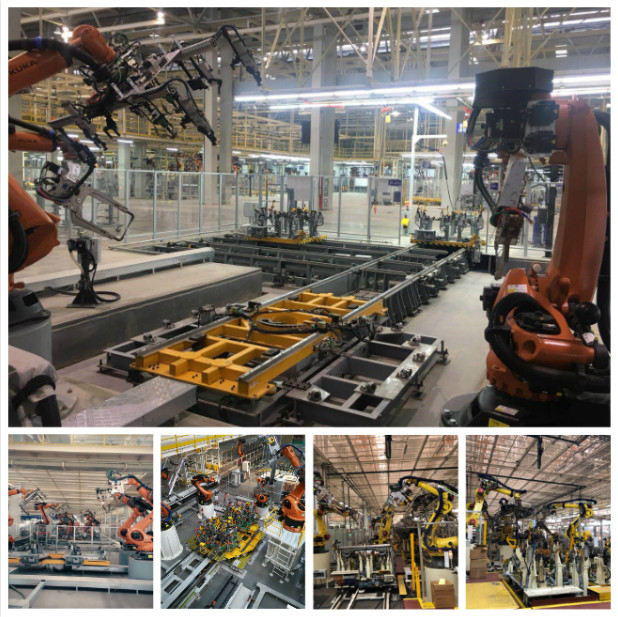

Flexible Floor Welding System

1. Process introduction:

The floor welding line flexible system mainly completes the

assembly and welding work of the front, middle and rear floors and

engine compartment. The floor line can realize the flexible

switching of two types of models. Using the core technology of the

flexible sliding table and the split switching system, the middle

floor area and the rear floor area can be welded together in one

line. The production cycle can be 60JPH, and the automation rate

can reach more than 90%.

Pic1

Pic2

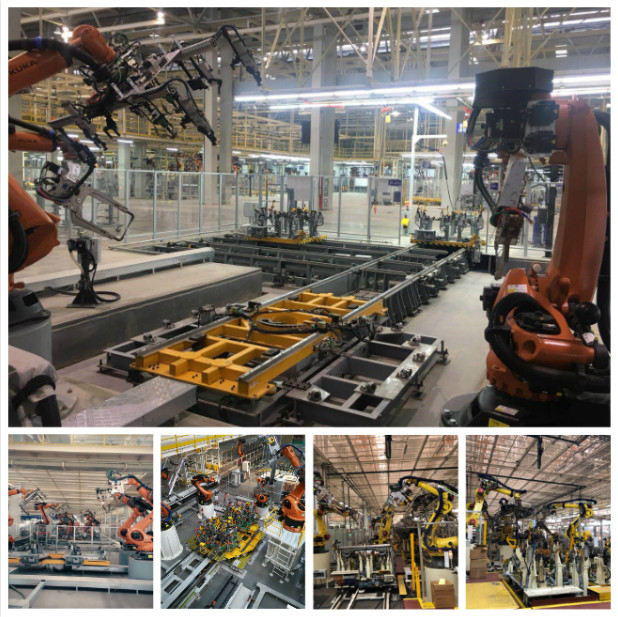

2. Project case:

Pic1-3

1. Accompanying trolley through production line

The typical form of this production line is shown in Figure 4. It

generally adopts the same trolley-type fixtures in different

quantities, and is driven by a chain to a predetermined station.

After manual feeding and manual welding, each car body is placed on

the same fixture and different working stations. Complete the

assembly. This form of production line has low production

efficiency, high labor intensity, single-species special-line

production, and the accuracy and quality of products are not easy

to guarantee. It is a commonly used production form in the early

days and is generally suitable for small batch production.

2. Automatic production line for single vehicle

The typical form of the production line is shown in Figure 5. It

generally uses fixed special fixtures and cooperates with

manipulators for automatic welding and assembly. Materials are

automatically transported and put in by cranes, and reciprocating

shuttle machines are often used for product transportation between

each station. It is characterized by high production efficiency,

high degree of automation, and stable quality, but it is still a

single-species production line.

3. Multi-model automatic mixed production line

The form of this production line is basically the same as that of

the single-model automatic production line. The main difference is

that the main welding production line adopts multi-model mixed line

production, generally 1 to 3 models. The assembly fixture adopts

the special series connection method for each model. The investment

cost of this equipment is relatively high, and the independent

assembly fixtures and surrounding transport relations of each model

need to meet the requirements of the production capacity of the

whole line, and the equipment flexibility is poor, and the

investment efficiency of automation equipment is low.

The other way is to use a four-sided rotary fixture, which

automatically switches the corresponding production according to

different models, and the manipulator performs automatic assembly.

Its main form is shown in Figure 7. As for the floor sub-assembly

fixture, it is generally moved outside the main welding line to set

up the line independently. The main welding line is usually a

repair welding fixture except for the assembly fixture, which is

easier to share with multiple models.