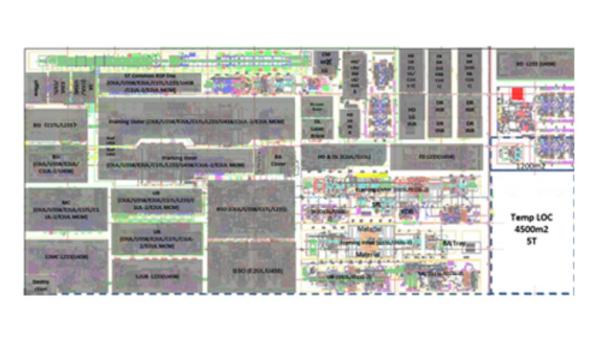

60JPH Automated Plant Aluminum Body

| Area | 10000m2 |

| Business Scope | Main line, Side panel, floor, closure line. Roof Assembly line |

| Models | 1+2(reserve) |

| Cycle Time | 10JPH (307s) |

| OEE | 85% |

| Automation Rate | 90% |

| Robots | 136 |

| Main Process | Aluminum Spot welding, Gluing, CMT Brazing. Automated Screwing,

Aluminum Laser Brazing, Roller hemming, FDS, SPR |

Fixture switching for flexible production

The key to the realization of a flexible production line is that

the same station can realize the switching of fixtures for

different models. In the process of body manufacturing, according

to different switching methods, it can be divided into overall

switching, partial switching and full servo switching.

Overall switching, the production station has multiple sets of

production fixtures, which means that during the production

process, a complete set of production fixtures is switched to the

production station by means of rotation or movement. There are

mainly rotary table switching, movable rotary table switching, and

trolley switching.

Partial switching mainly occurs when most of the positioning parts

of different workpieces are the same, and only some parts are

different. Among modern designs, many market-tested and approved

designs can be modularized, which makes full use of the

achievements of excellent designs and shortens the development

cycle. When the product is replaced, only the local positioning is

changed. The corresponding fixtures are only partially changed. In

the body production, the floor positioning only needs to switch the

positioning of the rear wheel cover, so the main line trolley often

performs partial switching at the wheel cover.

Theoretically speaking, a sufficiently fine servo fixture can be

applied to various models according to the digital model. The

future servo fixture can use one station, reducing the number of

trolleys and fixtures, and greatly saving space.